WINLEE DuraMax Power System

Redefining battery performance standards, leading the era of long‑range endurance

High‑density ABS engineering plastic plus carbon fiber composite deliver greater conductivity and durability, providing a more stable, longer‑lasting power core for electric vehicles.

At WINLEE, we believe energy is not just power — it is the foundation of trust. DuraMax batteries inherit advanced material science and strict industrial standards to deliver a new generation of power batteries featuring high energy density, strong stability, and low degradation.

Designed for Middle Eastern climates — from hot deserts to humid coasts — DuraMax delivers steady, sustained power so every journey starts with confidence.

Learn MoreCore Materials

Advanced material science for a superior performance foundation

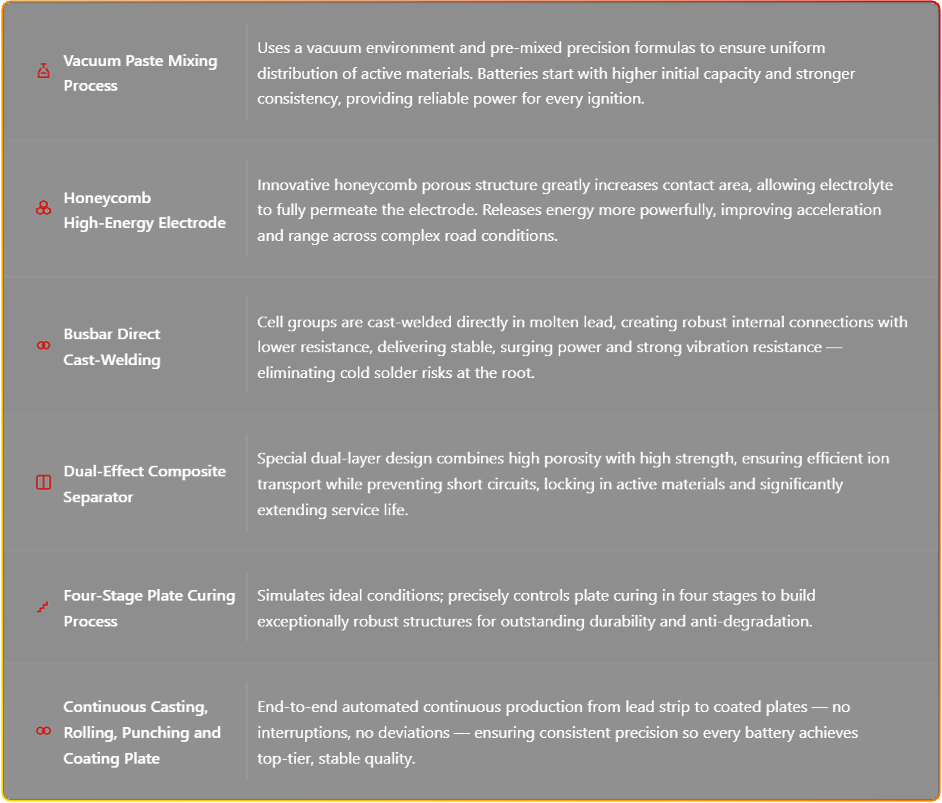

Battery Manufacturing

Precision manufacturing ensures exceptional quality for every battery

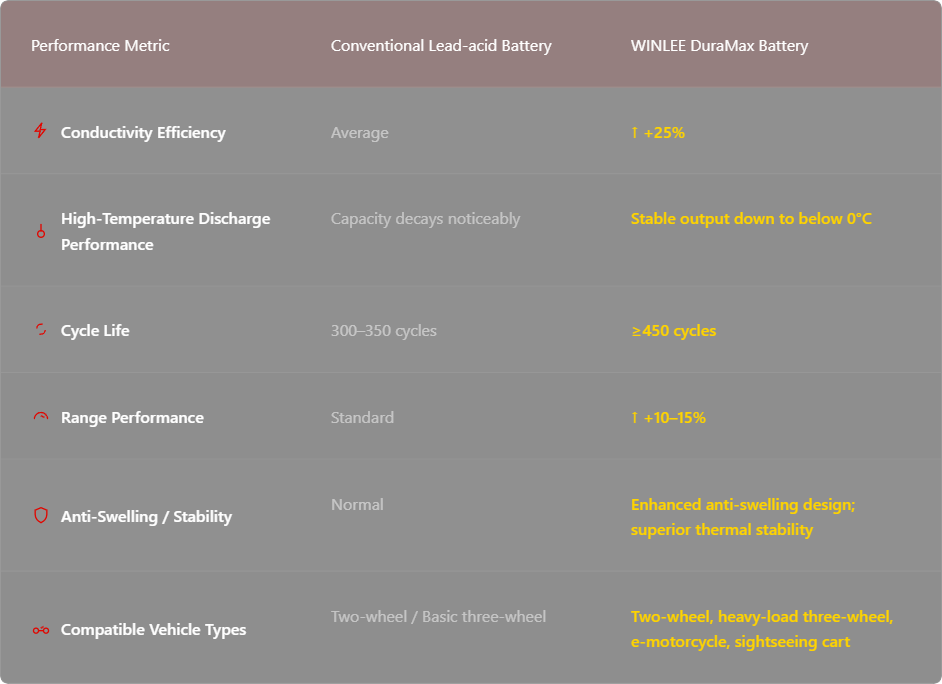

Compared with Traditional Batteries

Performance surpasses across the board, defining the next‑generation power standard

Built for more demanding roads and environments

Adapted to diverse scenarios; ready for rigorous demands

High‑temperature Regions

Graphene structure reduces heat buildup, effectively preventing swelling and capacity fade.

Long‑distance Commuting

High‑capacity design for extended endurance.

Heavy‑load Models / Slope Operation

High instantaneous output power for stronger performance.

Humid Environments / Dusty Climates

Rare‑earth anti‑corrosion process extends service life.